Research and

Development

Research and Development with the spirit of

“Unending Creation and

Challenge,”

has been our corporate DNA from its inception.

Here are some achievements Araki’s dynamic

technologies have made.

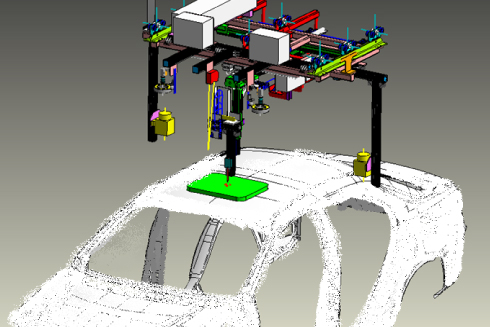

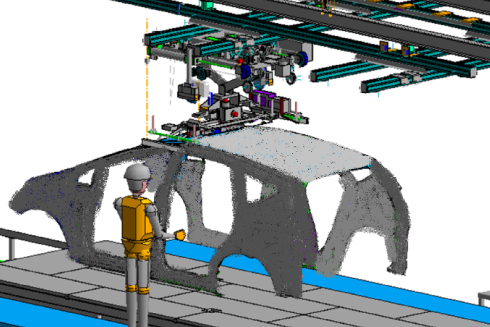

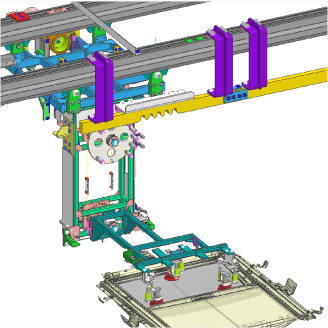

High Precision Non-Contact Synchronization

Product Information

This is high precision synchronization equipment developed for automobile assembly line that synchronizes a vehicle conveyor with and hanging equipment. The conventional type of conveyor with tracking system incorporated, which was controlled by encoder values, used to result in an approximately 5-10 mm margin of error.

However, by this newly developed technology applying a position tracking system by camera, we were able to reduce the margin of error below 0.75-1.5 mm. By this success of development, the reduction of risk caused by narrowed distance during the synchronous operation has been made, while automatic operation with work pieces on the vehicle have become possible.

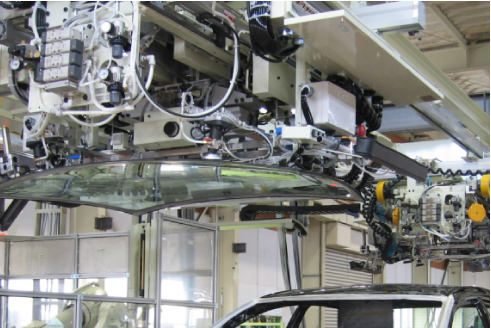

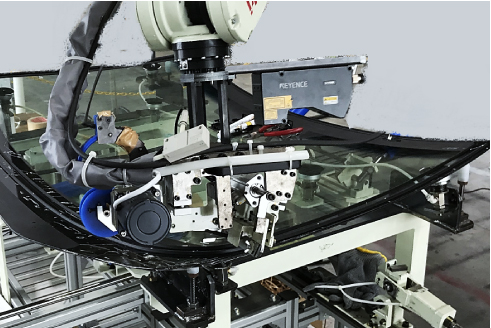

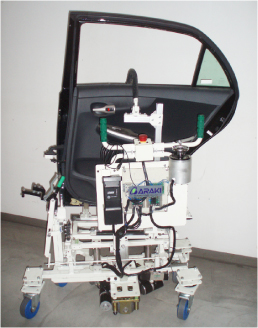

Glass Installation Assist Robots

Product Information

The glass installation work, which was formerly carried out by two skilled workers in tune, has been replaced by the new technology enabling one worker and one robot to work in collaboration. There are 3 major technologies that are introduced to this method as follows;

- ”Skill Assist Technology” that allows to input a worker’s operational ability by force sensor and to control impedance

- ”Variable damping control” adjusting to operating ability by changing viscos resistance

- Guiding function to activate ON/OFF according to the operational direction

- Awarded “Technical Innovation Award” by the Robotics Society of Japan

The Robotics Society Journal Vol.28, No5, PP. 624-630 In reference to the Robotics Society

Awarded “Technical Innovation Award”

by the Robotics Society of Japan

Automatic Rubber Seal Installation Equipment

Product Information

The technology of this product automatically installs rubber seals in Fr/Rr of automobiles.

By putting a constant pressure along the adhered surface, the robot installs seals. This technology can be applied to the former process such as alcohol cleansing and primer coating, which will provide an improvement of the process in the production sites.

The accuracy rate of ±0.5 has been achieved at the Robot speed of 200 mm/sec.

Karakuri Chuck (Ingenious Chucking Mechanism)

Product Information

In order to hold workpieces, robots and conveyor equipment are equipped with a holding device called “Hands” (or robotic claws).

By our technology with the Karakuri chuck mechanism, the claws have become possible to open and close without external power supply.

By this achievement, the reduction of weight has been attained, and the wiring of the tip end area has become unnecessary. Thus, significantly contributing to the streamlining of the whole equipment.

In the durability testing with engine parts, this Karakuri Chuck has successfully cleared the durability test more than 100,000 times.

Reversing Machine with “Karakuri” or ingenious mechanism

Product Information

Conventionally, the driving operation and the reversing movement of the equipment were controlled separately by each drive motor.

This technology of reversing machine with Karakuri mechanism has significantly improved the situation of factory sites, as the driving operation and reversing movement can be made by only one drive motor simultaneously, by transmitting the driving force to the inversion axis.

- This technology was highly evaluated by Toyota Motor East Japan Inc. and awarded “Technology Development Award.”

Omnidirectional Dollies

Product Information

This is a driving unit with multidirectional axis and assisting mechanism called “omni-wheel” integrated into one system.

This omnidirectional dolly can be combined with any equipment that runs on the shop floor by low thrust motor, as it can be operated in 360°of all directions, while maintaining the stable condition assured.

Contact Us

Please contact us for further information,

questions and inquiries as follows.