Automatic Conveyance Equipment

Since the development of inter-process conveyor equipment for the

automatic welding process of automobile production lines in 1967,

Araki, as a comprehensive manufacturer of mid-distance conveyance

equipment, has increased lineups, while satisfying various needs of

customers.

It was indeed a great honor for Araki to support the production of more than 10 million units of cars behind the scene of auto manufacturing.

With the reliability obtained through those achievements as our competitive advantage, we will continue to explore the unexplored possibilities of a wide variety of smart conveyance technologies.

- Overwhelming Lineups of

Conveyance Equipment with Unrivalled

Quality and Reliability - Unparalleled Conveyance System of

Excellence provided by Engineering Expertise - Superior and Reliable Construction Technology

at High Elevation Platform

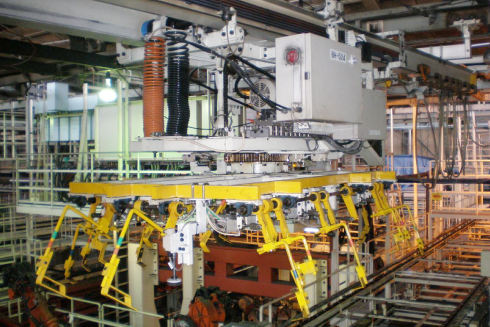

Overhead Conveyance Equipment

Product Information

This overhead conveyance carrier is designed to run on a railway on which power supply cables are wired for the effective use of a space in an assembly plant. The carrier has a lifter function that makes the holding parts (claws) move vertically by chain.

A plurality of conveyance equipment adjusting to the weight of workpieces are provided to respond to the needs of different types of production processes. We also cope efficiently with various forms of workpieces by designs specifically for the holding parts (claws).

In line with the layout of production factory, we add curved configuration to railway as well as branching and joining structures. We can also make a slope climbable up to 60 degrees at the maximum.

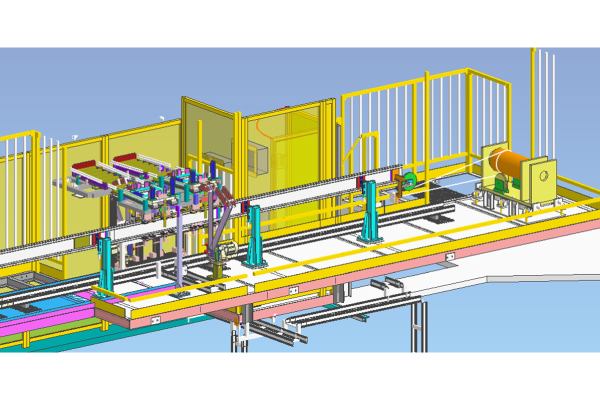

Wire Driven Type Conveyor System

Product Information

The wire type conveyer system has the mechanism designed to carry a workpiece connected with motor driven wire put on the conveyance routes. Since it has an external driving system, the weight reduction of the moving body is obtained, thus the equipment becomes a slim configuration, and it attains fast movement with less noise.

In addition, this system is suited to use in a clean environment, for it needs no power supply trolley.

- Conveyance Speed: 200m/min maximum

- Conveyance Distance: Shuttle Conveyance of 50 m at maximum

- Load Capacity: 300 kg maximum (weight of dolly included)

Various Type of Conveyers

Product Information

Araki offers various types of conveyors including chain conveyors from a large sized chain conveyor for loading large workpieces like automobiles, to a low driving force conveyor designed to handle light weight parts.

We help our customers from the process planning stage with many of our experienced industrial engineers on conveyance systems.

We provide advice on application of conveyor systems in such special cases of environment as follows.

- ・Welding Process

- ・High Temperature Process

- ・Human-Robot Collaboration Process

- ・High Humidity Process

- ・Etc.

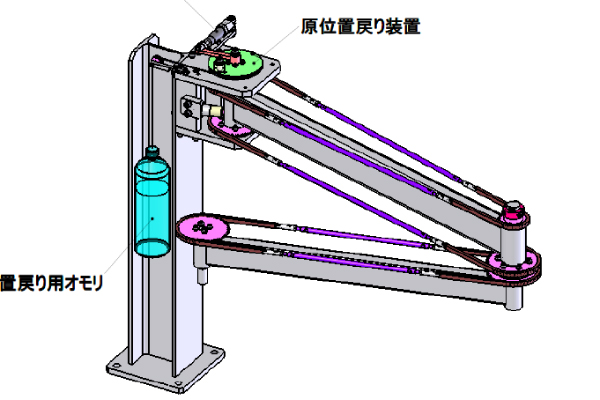

S Arm

Product Information

S Arm is a conveyor equipment utilizing a parallel mechanism, which does not need rails. As it moves parallel in a stable condition of load maintained with the same posture of a work piece kept as it stands, it is suited to incorporate in both a manual work line and automatic equipment.

- Load Capacity: 20-50kg

- Conveying Distance: 2-6m

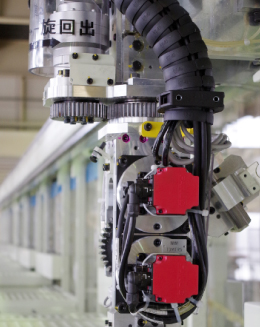

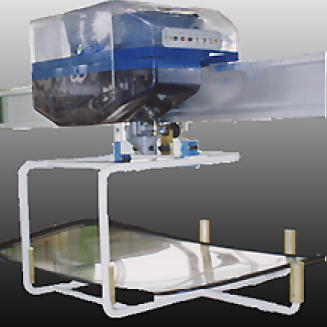

Gantry Loader

Product Information

Araki manufactures and sell Gantry Loader for inter-process conveyance of machining process, etc. We have unique lineups of Araki original such as “Karakuri” Chuck that enables to function with less driving force, and a wire driven type of loader.

High Speed Train System

Product Information

This is a conveyance system Araki has developed for long distant use at plant sites. A shuttle runs on aluminum railway at the maximum speed of 500 mm/min. We are ready to offer a runway slope (up to 30°) and a curved layout, etc. as an option. Please feel free to contact us.

Palletizer

Product Information

Araki manufactures and sell automatic palletizers mainly for the stamping processes of automobile production line. It is an automatic system that a robot takes out a body panel formed by stamping machine and loads into the specified pallet. In addition, we ingeniously create one integrated system of operation by interlocking pallet stacking and destacking devices, as it is one of the areas of our expertise.

AGV System

Product Information

Araki offers various types of AGV carrier systems as a solution to realize efficient ground conveyance. We have been producing an AGV with small load capacity as well as the one that carries a heavy weight workpiece exceeding 4 tons.

Araki also meets the needs of customers as a system integrator through various challenges, including the reevaluation of entire process cycles in collaboration with AGV makers.

Contact Us

Please contact us for further information,

questions and inquiries as follows.